Apr 19, 2025

Apr 19, 2025

Feb 22, 2025

Mike Dooley

In the paper processing industry, every link pursues efficiency and precision. From the initial production of paper to the final molding of the finished product, a series of complex processes are closely linked. Among them, the Paper Pile Turner Machine, as a key equipment, is quietly changing the working mode of paper processing, especially the coordinated use with large paper cutters, which has brought significant benefits to the industry.

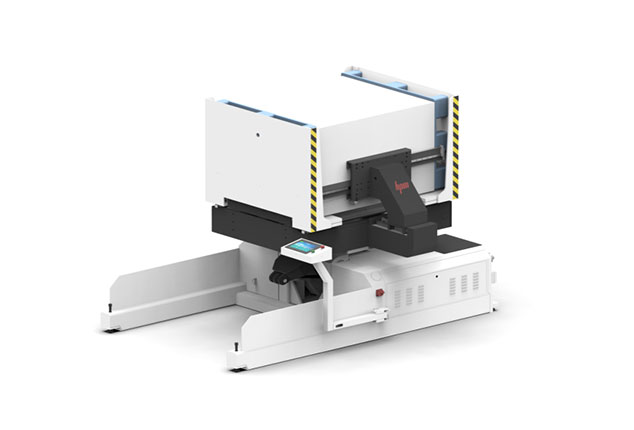

As the name suggests, a Paper Pile Tnrner is a mechanical equipment specifically designed for paper stacking. Its core task is to turn neatly stacked paper smoothly. In the process of paper processing, paper often needs to be processed in different directions, and manually turning a large amount of paper is not only inefficient, but also easy to cause damage to the paper and uneven stacking. The Pile Turner With Touch Screen perfectly solves these problems. It has a sturdy and well-designed clamping device that can firmly grasp the paper stack, and then use an advanced power system to accurately turn it at a preset angle to ensure that the paper is not damaged during the turning process, laying a good foundation for subsequent processing procedures.

The working principle of the Paper Pile Turner Machine combines precision mechanical design, automatic control and advanced sensing technology. Its mechanical structure is mainly composed of a base, a lifting device, a rotating shaft and a clamping component. When it is necessary to turn over the paper stack, first, the lifting device adjusts the clamping component to a suitable height so that it can accurately align with the paper stack. Then, under the command of the control system, the clamping component quickly and firmly clamps the paper stack. At this time, the rotating shaft starts to rotate under the drive of the motor, driving the entire clamped paper stack to turn smoothly. In this process, various sensors play a key role. The position sensor monitors the position of the paper stack in real time to ensure that it is always in the correct trajectory during the turning process; the pressure sensor always detects the clamping force of the clamping component on the paper stack to avoid damaging the paper due to excessive force or causing the paper to slip due to insufficient force. Through the coordinated operation of these technologies, the Paper Pile Turner Machine can achieve high-precision and high-efficiency turning operations.

1. Improving production efficiency: Paper cutting is an important process in the paper processing process. The Pile Turner With Touch Screen and the large paper cutter can be used together to achieve seamless connection. When the paper stack is turned to the appropriate angle, it can be directly and quickly transported to the large paper cutter for cutting. This continuous operation process greatly reduces the time for paper to be transferred between different devices, greatly improving production efficiency. Compared with the traditional method of manually turning over the paper stack and then cutting the paper, the combined equipment can process more paper per unit time to meet the growing market demand.

2. Guarantee cutting accuracy: When cutting paper, the large paper cutter has extremely high requirements for the placement angle and neatness of the paper. The Paper Pile Turner Machine can accurately turn the paper stack to the angle required by the paper cutter, ensuring that the paper is evenly stressed during the cutting process, thereby greatly improving the cutting accuracy. Whether it is office paper with uniform cutting specifications or special paper with strict precision requirements, the combined equipment can ensure that the size of the paper after cutting is accurate and correct, reducing the waste of paper caused by cutting errors.

3. Reduce labor intensity: The work intensity in the paper processing industry is relatively high, especially the manual handling and turning of paper stacks, which is a great test for the physical strength of workers. The combination of Paper Pile Turner Machine and large paper cutter realizes automatic operation and greatly reduces the links of manual intervention. Workers only need to monitor the operation of equipment and perform some simple auxiliary operations, which greatly reduces the labor intensity, reduces the operating errors caused by manual fatigue, and improves the safety of the production process.

1.Printing paper processing: In the printing industry, large-sized paper needs to be cut into various specifications to meet different printing needs. The combination of paper pile turner machine and large paper cutter can quickly turn the paper stack and cut it into suitable sizes, providing efficient support for pre-printing preparations. Whether it is offset paper for book printing or coated paper for exquisite album printing, it can be accurately processed by this combined equipment.

2. Packaging paper production: The packaging industry also has very strict requirements on the specifications and quality of paper. The pile turner machine works together with the large paper cutter to turn the base paper stack and cut it into the paper size required for various packaging, such as carton paper, paper bag paper, etc. This not only improves the production efficiency of packaging paper, but also ensures the quality of paper, making the packaging products more beautiful and firm.

3. Special paper processing: For some papers with special properties, such as thermal paper, carbonless copy paper, etc., the processing process requires higher precision and stability. The combination of paper pile turner machines and large paper cutters, with their precise operation and stable performance, can meet the processing needs of special papers, ensure that these special papers are not damaged during the processing process, and maintain their unique properties.

The combination of pile turner machines and large paper cutters has become an important means for the paper processing industry to improve production efficiency and ensure product quality. With the continuous advancement of science and technology, the performance of these two devices will continue to be optimized, bringing more innovation and development opportunities to the paper processing industry. In the future, we have reason to believe that they will play a more important role in the field of paper processing and promote the entire industry to a higher level of development.

GET A QUOTE