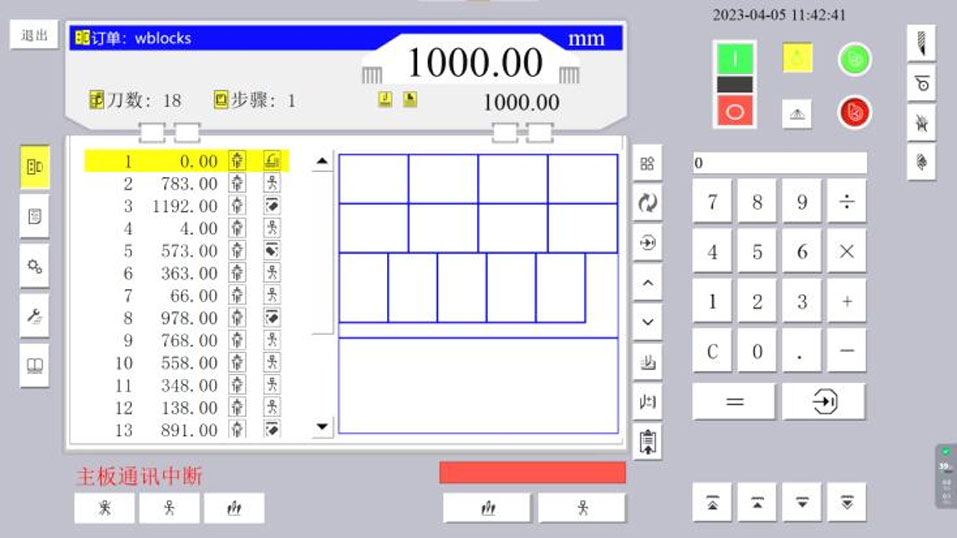

16 inch full touch display screen, with program setting. German operating system is equipped to meet the operating habits of domestic users and guarantee convenient operation; Mainboard adopted industrial chip imported from Italy

16 inch full touch display screen.

Max. backgauge speed is 20m/min;Display precision is 0.01mm.

Intelligent planning and cutting system for white material

.Electronic Lock Safety Device

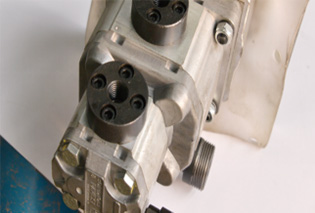

Hydraulic System

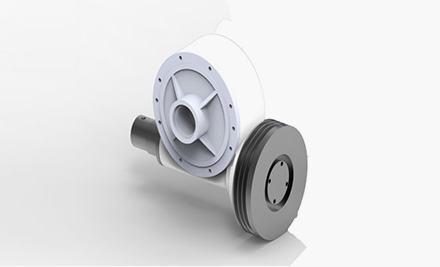

Oil Pump

Remote Control System

Security Photoelectric

INOVANCE Servo Motor

HPM PLC

1.Mainboard adopted industrial chip imported from Italy

2.Equipped with signal amplification function and excellent anti-interference to avoid dimension errors due to drive aging

3.Dimension in front of knife will be displayed to facilitate sizes for cutting

4.Program storage capacity is 300 programs, each program can store 200 items cutting size

5.computing with four operations, output programs in real time

6.Equipment has relative positioning function relative to current position

7.With minimal compensation, it can rapidly correct program errors due to paper distortions

8.It can rapidly find out user-defined number of cutters

9.Each air cushion program can be programmed

10.The time of automatic cutting signals can be set up and cancelled; single automatic cutting can be started by inputting a password

11.High and low speeds can be manually switched over rapidly

12.A paper-pushing program is equipped to push paper automatically so as to guarantee safety and enhance operation efficiency

13.Automatic cutting can be made as per instructed programming

1.16 inch full touch display screen.

2.Max, backgauge speed is 20m/min.

3.Display precision is 0.01mm.

4.Manual and automatic operations can be choose.

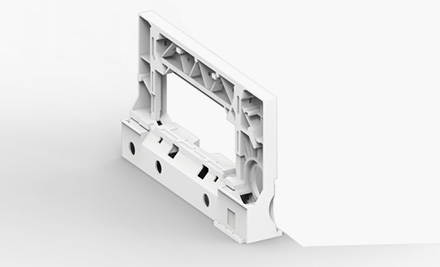

Gantry casting structure is adopted to ensure high-precision of the structure in the assembly process, which improves the rigidity and stability of the cutter.

Worm gear system: large size worm gear, more cutting force, cutting more stable.

The knife bed adopts long slotted hole, which is convenient for quick knife change and adjustment.

Knife bed puller to ensure the safety of the machine, when the safety bolt is loose or broken, the machine will stop directly, without damaging the machine.

The fully enclosed air cushion device makes paper movement very light and smoother.

The paper pusher is linearly double guide rail guided and ball screw driven for smooth operation and precise positioning.

Integrated seamless working table with chrome-plated surface and good structural strength.

|

No. |

Name |

Brand, specification & model |

CE Standard(Optional) |

|

1 |

Background LCD |

16’’Color touch Interface |

|

|

2 |

PLC |

HPM |

Panasonic |

|

3 |

Backgauge position motor |

INOVANCE servo motor |

Panasonic |

|

4 |

Pick-up |

FOTEK |

|

|

5 |

Limit switch |

TE |

|

|

6 |

Guarding motor |

TE |

|

|

7 |

Air switch |

TE |

|

|

8 |

AC Contactor |

TE |

|

|

9 |

Miniature relay |

IDEC |

|

|

10 |

Switching power supply |

TE |

|

|

11 |

Power switch |

CANSEN |

|

|

12 |

Press-button |

TE |

|

|

13 |

Ball screw |

High accurate (HIWIN) |

|

|

14 |

Linear guider |

High accurate double linear Guides (JSM) |

|

|

15 |

Hydraulic system |

Combination Valve(VIS) |

WESSEL(Germany ) |

|

16 |

Oil Pump |

RYAN |

BONDIOLI(Italy) |

|

17 |

Main Bearing |

NSK |

|

|

18 |

Work Table |

Slotless and plated chromium work table |

|

|

19 |

Photocell |

Sheng da |

AB(America) |

|

20 |

Knife |

HSS |

|

|

21 |

|

|

Closing cover |

|

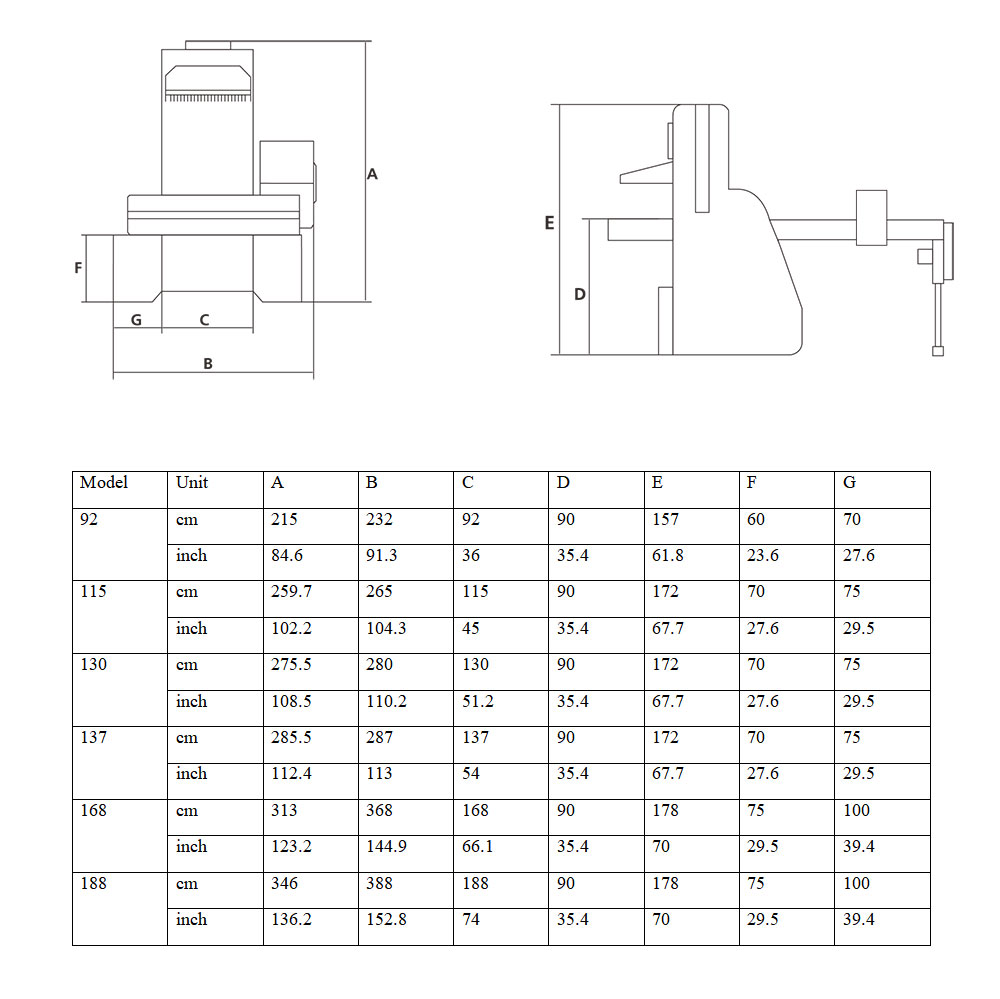

Model |

Unit |

92 |

115 |

130 |

137 |

168 |

188 |

|

Max.Cutting Width |

cm |

92 |

115 |

130 |

137 |

168 |

188 |

|

|

inch |

36.2 |

45.3 |

51.2 |

53.9 |

66.1 |

74 |

|

Max.Cutting Length |

cm |

92 |

115 |

130 |

145 |

168 |

188 |

|

|

inch |

36.2 |

45.3 |

51.2 |

57.1 |

66.1 |

74 |

|

Max. Cutting Height |

cm |

12 |

16.5 |

16.5 |

16.5 |

16.5 |

16.5 |

|

|

inch |

4.7 |

6.5 |

6.5 |

6.5 |

6.5 |

6.5 |

|

Min. Cutting Size (without false clam plate) |

cm |

2.5 |

3 |

3 |

3 |

3 |

3 |

|

|

inch |

1 |

1.2 |

1.2 |

1.2 |

1.2 |

1.2 |

|

Min. Cutting Size (with false clamp plate) |

cm |

9 |

9 |

9 |

9 |

9 |

9 |

|

|

inch |

3.5 |

3.5 |

3.5 |

3.5 |

3.5 |

3.5 |

|

Front Table Length |

cm |

63.2 |

71.5 |

73 |

73 |

75 |

75 |

|

|

inch |

24.9 |

28.1 |

28.7 |

28.7 |

29.5 |

29.5 |

|

Max.Clamp Pressure |

N |

30000 |

40000 |

40000 |

45000 |

60000 |

70000 |

|

Max. Cutting Speed |

time/min |

45 |

46 |

46 |

46 |

46 |

46 |

|

Main Motor |

KW |

3 |

4 |

4 |

4 |

8.5 |

8.5 |

|

Net Weight |

Kg |

2300 |

3700 |

3900 |

4100 |

6200 |

6600 |

|

Gross Weight |

Kg |

2500 |

4100 |

4300 |

4500 |

7000 |

7400 |

|

Packing Size(L×W×H) |

cm |

228×140×188 |

285×190×210 |

285×190×210 |

310×190×210 |

360×205×220 |

380×205×220 |

GET A QUOTE