Paper loader has many features such as high production efficiency, reduced labour intensity of the operator, short auxiliary production time and reduced labour costs. The automatic paper pick-up function automatically transfers the paper from the pile to the working platform, making the operation process safe and reliable. The machine is protected by a safety edge during operation. This ensures the safety of people around the machine during operation.

Machine Series: QZ

Paper Grammage: 50

Computer Screen: MCGS

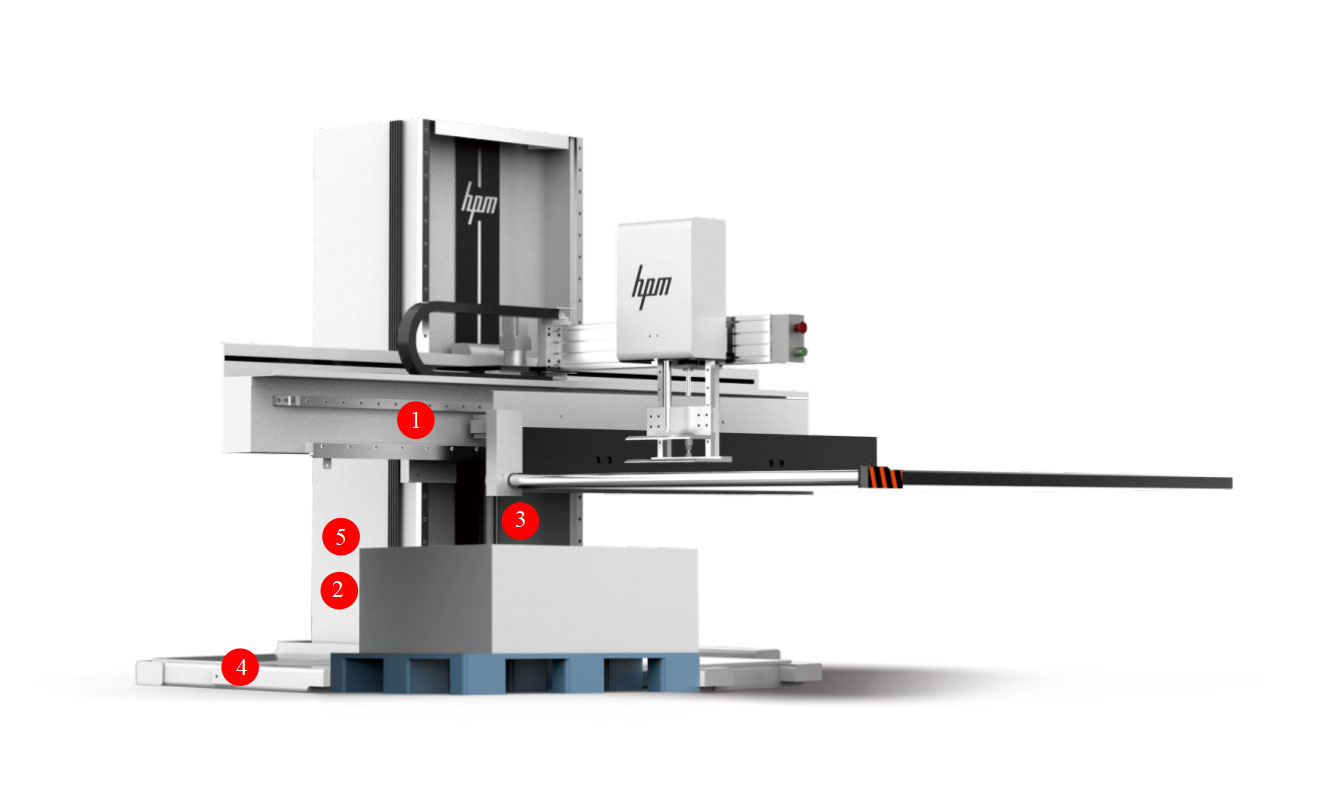

High quality steel beam, durable.

Hydraulic lifting system, energy saving and low maintenance cost.

Hydraulic lifting system, energy saving and low maintenance cost.

Adopting the patented overall frame type welded square steel structure base

Multi-servo control drive mechanism

Operating system co-developed with INOVANCE Technology

1.Paper loader has many features such as high production efficiency, reduced labour intensity of the operator, short auxiliary production time and reduced labour costs.

2.The automatic paper pick-up function automatically transfers the paper from the pile to the working platform, making the operation process safe and reliable.

3.The machine is protected by a safety edge during operation. This ensures the safety of people around the machine during operation. The paper pick-up height can be adjusted at will. The hydraulic structure is used for lifting and lowering to ensure a smooth lift. The paper clamping function is pneumatically operated and the tightening force is adjustable for different paper types.

4.Greatly facilitates the picking up of paper stacks during the cutting process. It provides the necessary prerequisites for future printing or folding processes, saving time and effort. The fully automatic paper pick-up function ensures simple operation.

|

No. |

Name |

Brand, specification & model |

Origin of brand |

|

1 |

Sensor |

FOTEK |

Taiwan |

|

2 |

Air Switch |

TE |

France |

|

3 |

AC Contactor |

TE |

France |

|

4 |

Button |

TE or Eton |

France |

|

5 |

Platform servo motors |

Platform Walking(Inovance) |

China |

|

6 |

Servo Driver |

Walking Control(Inovance) |

China |

|

7 |

Servo motor |

Pick-up part(Inovance) |

China |

|

8 |

Photoelectric Sensor |

Detecting the height of paper stacks(LEUZE) |

German |

|

9 |

Switch Power |

TE |

France |

|

10 |

Power Switch |

CANSEN |

China |

|

11 |

Miniature Relay |

TE |

France |

|

12 |

Combination valves |

Hydraulic Part(WAISN) |

Taiwan |

|

13 |

Air cylinder |

Catch paper part(AirTAC) |

China |

|

15 |

Linear Guider |

High accurate linear guides |

Taiwan |

|

16 |

Display screens |

MCGS |

China |

|

Model |

Unit |

QZ1450F |

QZ1650F |

QZH1450F |

QZH1650F |

|

Loading Pattern |

|

Pre-paper |

Pre-paper |

Rear |

Rear |

|

Plate Size (W×L) |

cm |

130×128 |

160×200 |

130×160 |

160×200 |

|

Max.loading size (W×L) |

cm |

110×168 |

130×170 |

102×130 |

132×168 |

|

Min.loading size (W×L) |

cm |

45×56 |

52×62 |

45×56 |

52×62 |

|

Max.loading height |

cm |

16.5 |

16.5 |

16.5 |

16.5 |

|

Max.Stacking height (with plate) |

cm |

160 |

160 |

160 |

160 |

|

Min. table height from the floor |

cm |

15 |

15 |

15 |

15 |

|

Max.loading weight |

Kg |

350 |

450 |

350 |

450 |

|

Pressure setting |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

|

Air Demand |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

|

Air supply consumption |

L /min |

3 |

3 |

3 |

3 |

|

Rated voltage |

V |

380/220 |

380/220 |

380/220 |

380/220 |

|

Power supply mode |

|

Three-phase five-wire system |

Three-phase five-wire system |

Three-phase five-wire system |

Three-phase five-wire system |

|

Gross Power |

Kw |

5 |

5.8 |

5.7 |

6.5 |

|

Min.grams of paper |

g |

50 |

50 |

50 |

50 |

|

Loading Time |

S |

25-40 |

25-40 |

25-40 |

25-40 |

|

Net Weight |

KG |

1850 |

2350 |

1900 |

2400 |

|

Gross Weight |

KG |

1950 |

2500 |

2000 |

2550 |

|

Machine Size (L×W×H) |

cm |

277.3×232.3×206 |

333×263×206 |

290×231×206 |

315×270×206 |

|

Packing Size (L×W×H) |

cm |

270×228×221 |

312×226×221 |

288×230×221 |

312×226×221 |

GET A QUOTE